-

Mail us

contact@tiger-transformer.com -

Phone us

(+86)15655168738

Mail us

contact@tiger-transformer.comPhone us

(+86)15655168738Absolutely not!

Due to its high energy density and special chemical properties, lithium batteries must use a power management chip, that is, a charger IC, for safety and life considerations. ); In addition, the charging chip can optimize the charging curve to the greatest extent, and combined with the software algorithm, it can ensure the service life of the battery under the conditions of fast charging, and at the same time greatly improve the safety of the charging process. sex. Let’s first look at a commonly used charging chip.

Power Management

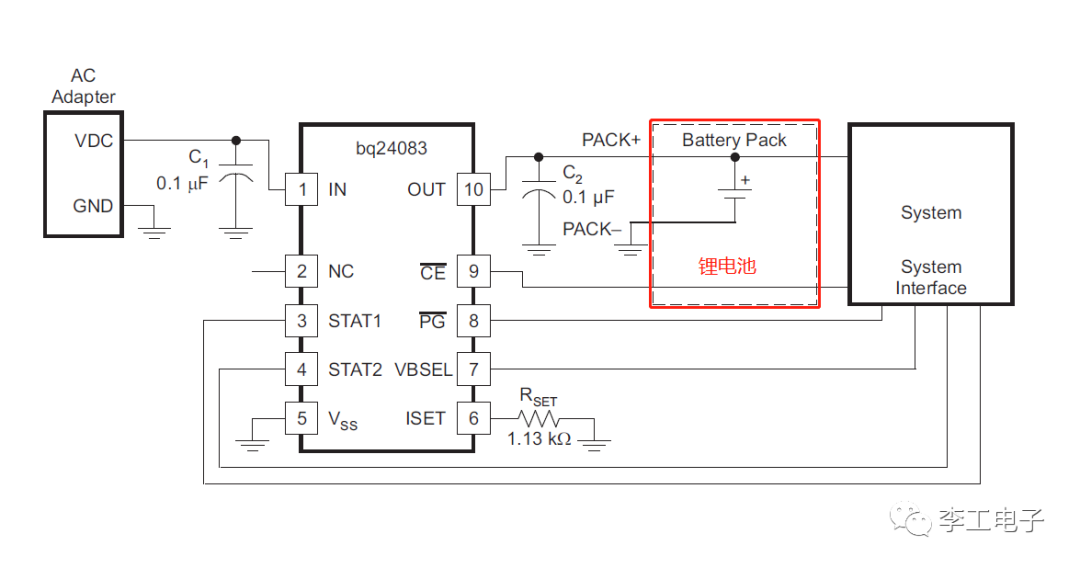

This is a charging IC from TI. It is mainly used to charge lithium batteries for consumer electronics products. The red part is the lithium battery pack (some have a temperature sensor inside). The chip charges the battery through the OUT pin. It supplies power to the battery pack and is also the main power supply of the entire system. Its ISET pin can set the maximum value of the charging current to prevent the current from exceeding the maximum value that the battery pack can withstand. Let's continue to look at the internal structure of the charging IC.

Charging chip

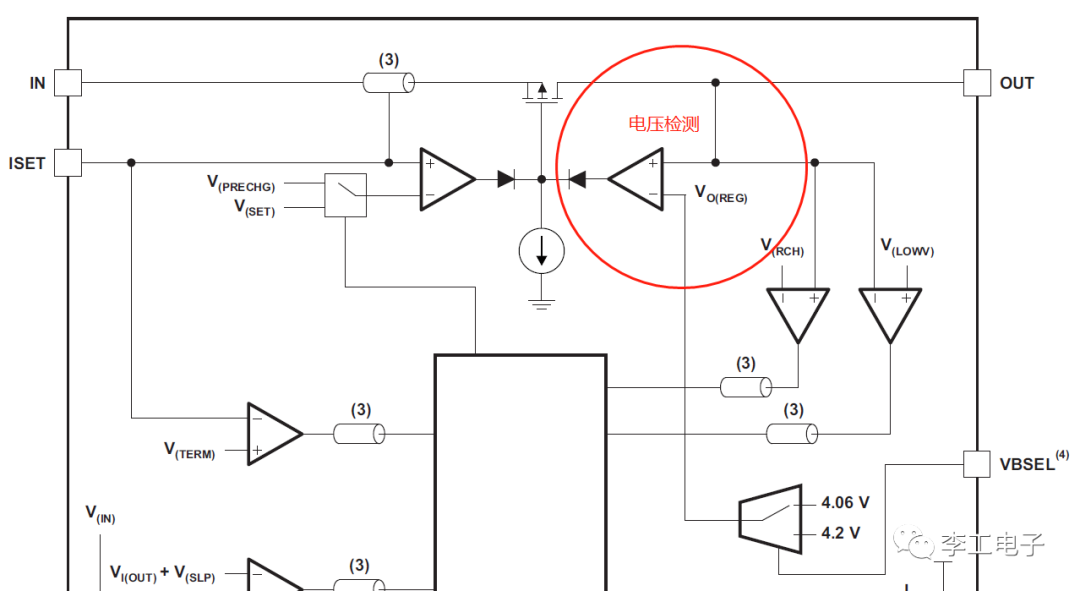

This makes it clearer. The red marked part plays a key role in the lithium battery charging process. Through the OUT terminal, it can detect the voltage value of the battery pack in real time, plus calculate the charging current. , you can get the power of the battery pack at this time (equivalent to a fuel gauge). Once the current status of the battery pack is determined, the corrected fuel gauge model can be used to determine which charging mode to use.

Charging curve

So what is the charging mode? Here is a brief introduction to science. Our friends who like to play with digital devices should often hear about fast charging of mobile phones (terms such as charging for five minutes and talking for two hours...). Fast charging generally refers to the 3C charging mode. For example, the capacity of a lithium battery is 580mAh. When the charging current is 3 times the battery capacity value (3*580), that is, 3C charging, a charging current of about 1.7A. After understanding what fast charging is, the next step is the common lithium battery charging mode.

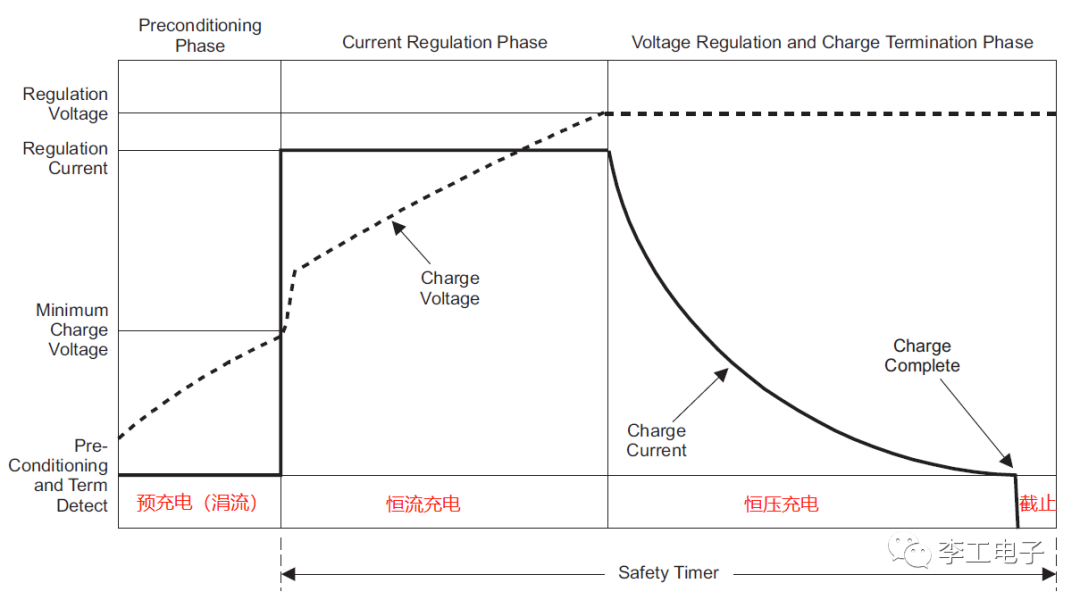

This is a charging curve, looking from left to right (The dotted line is the voltage, the solid line is the current). When the battery first starts charging, the charging current is very small, which is equivalent to "warming up" the battery and extending the battery life. This stage is called "Trickle Charging ”, that is, pre-charging; when the battery is ready, it can start high-current (3C) charging. This stage is called “Constant current charging”, And if this When the chip detects that the temperature of the battery pack is too high, the charging current will drop to 2C or 1.5C, etc. When the temperature drops, charging will resume at 3C, and so on.

If the battery pack voltage reaches a certain inflection point (usually determined by the chip), for example, a 12V battery, assuming its inflection point is 9V, that is to say, when the battery pack voltage reaches about 9V, charging The chip will enter the next stage, which is "Constant voltage charging". At this time, the charging voltage value changes very little, but the current value drops quickly.

This principle is very simple. For example, we use a bucket to fill water. At the beginning, do not open the faucet too much (trickle), because the water in the empty bucket will splash. When there is a certain amount of water at the bottom of the bucket, If the water level is high, you can turn the faucet to the maximum (constant flow) and fill it with water as quickly as possible. Finally, the water in the bucket is almost full. In order to prevent the water from spilling out, should we turn down the faucet? The water flow is like electric current, this is "Constant voltage charging".

Battery Model

The last step of charging, "cutoff", is also very important. Each charging chip has a default cutoff voltage (some are adjusted through software) . How do we judge when to stop charging? This requires popularizing a new concept: battery model.

Because the charging capacity calculated by the charging chip or fuel gauge is different from the actual charging capacity of the battery. The power value we calculated is only an ideal state value. It also needs to be combined with the battery model provided by the battery manufacturer to comprehensively judge the battery power value. If the calculated value deviates too much from the actual value, the fuel gauge model needs to be corrected based on the battery model to make the calculated value infinitely close to the actual value.

The battery model given by the manufacturer is based on complex verification tests, such as high and low temperature tests of the battery, high altitude tests, instantaneous temperature changes and other tests to verify the battery. Capacity changes in different environmentsfinally lead to this accurate battery model. Based on this model, we can estimate the current power value of the battery and when it will be fully charged, and the "cut-off" point can be calculated.

So back to your question above, even if you get a stable DC 12V power supply through a perfect BUCK, but without a power management chip and strict software algorithm, how can you ensure that the battery is still running? Under what conditions should you use what mode to charge? Furthermore, you can't even be sure whether the battery is fully charged (100%), because the last 1% of power often takes a long time.

In addition, from the perspective of charging safety, the inability to monitor the temperature inside the battery pack in real time undoubtedly increases safety risks!